Creation of consistent burn wounds: a rat model

E.Z. Cai, C.H. Ang, A. Raju, K.B. Tan, E.C.H. Hing, Y. Loo, Y.C. Wong, H. Lee, J. Lim, S.M. Moochhala, C.A.E. Hauser, and T.C. Lim

Archives of Plastic Surgery, 41 (2014) 317-324

BACKGROUND: Burn infliction techniques are poorly described in rat models. An accurate study can only be achieved with wounds that are uniform in size and depth. We describe a simple reproducible method for creating consistent burn wounds in rats.

METHODS: Ten male Sprague-Dawley rats were anesthetized and dorsum shaved. A 100 g cylindrical stainless-steel rod (1 cm diameter) was heated to 100℃ in boiling water. Temperature was monitored using a thermocouple. We performed two consecutive toe-pinch tests on different limbs to assess the depth of sedation. Burn infliction was limited to the loin. The skin was pulled upwards, away from the underlying viscera, creating a flat surface. The rod rested on its own weight for 5, 10, and 20 seconds at three different sites on each rat. Wounds were evaluated for size, morphology and depth.

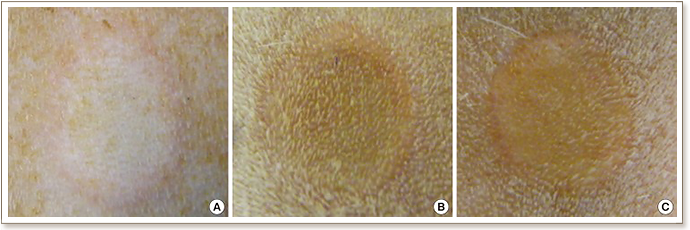

RESULTS: Average wound size was 0.9957 cm(2) (standard deviation [SD] 0.1845) (n=30). Wounds created with duration of 5 seconds were pale, with an indistinct margin of erythema. Wounds of 10 and 20 seconds were well-defined, uniformly brown with a rim of erythema. Average depths of tissue damage were 1.30 mm (SD 0.424), 2.35 mm (SD 0.071), and 2.60 mm (SD 0.283) for duration of 5, 10, 20 seconds respectively. Burn duration of 5 seconds resulted in full-thickness damage. Burn duration of 10 seconds and 20 seconds resulted in full-thickness damage, involving subjacent skeletal muscle.

CONCLUSIONS: This is a simple reproducible method for creating burn wounds consistent in size and depth in a rat burn model.

DOI: 10.5999/aps.2014.41.4.317

"KAUST shall be a beacon for peace, hope and reconciliation, and shall serve the people of the Kingdom and the world."

King Abdullah bin Abdulaziz Al Saud, 1924 – 2015

Thuwal 23955-6900, Kingdom of Saudi Arabia

Al-Haytham Building (Bldg. 2)

© King Abdullah University of Science and Technology. All rights reserved