Optimization of a 3D bioprinting process using ultrashort peptide bioinks

Z. Khan, K. Kahin, S. Rauf, G. Ramirez-Calderon, N. Papagiannis, M. Abdulmajid, C.A.E. Hauser

International Journal of Bioprinting 5(1),173, 2019

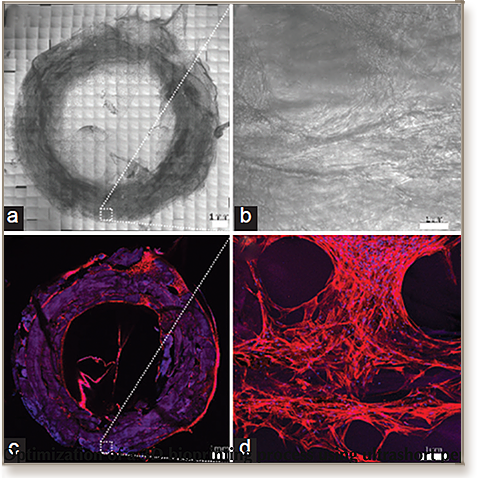

The field of three-dimensional (3D) bioprinting is rapidly emerging as an additive manufacturing method for tissue and organ fabrication. The demand for tissues and organ transplants is ever increasing, although donors are not as readily available. Consequently, tissue engineering is gaining much attention to alleviate this problem. The process of achieving well-structured 3D bioprinted constructs using hydrogel bioinks depends on symmetrical precision, regulated flow rates, and viability of cells. Even with the mentioned parameters optimized, the printed structures need additional refining by removing excessive liquids, as peptide hydrogel bioprints encapsulate water. However, it is challenging to eliminate the confined fluids without compromising the printing process. In this paper, we introduced a vacuum system to our 3D bioprinting robotic arm and thus optimized the printing quality for complex and refined 3D scaffolds. Moreover, the proposed vacuum system supports printing with cells. Our results show improved printing resolution which facilitates the printing of higher and more stable structures.

DOI: http://dx.doi.org/10.18063/ijb.v5i1.173

"KAUST shall be a beacon for peace, hope and reconciliation, and shall serve the people of the Kingdom and the world."

King Abdullah bin Abdulaziz Al Saud, 1924 – 2015

Thuwal 23955-6900, Kingdom of Saudi Arabia

Al-Haytham Building (Bldg. 2)

© King Abdullah University of Science and Technology. All rights reserved